Description

- Low cost closed loop system compared to servo motors

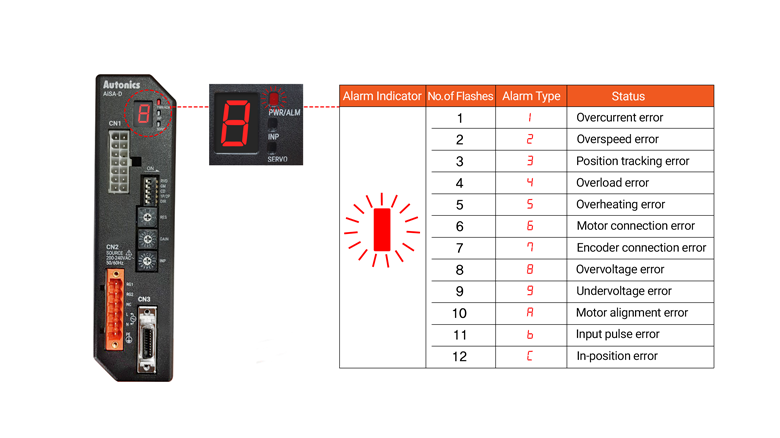

- 7-segment display for alarm/status reading

- Quick response rates for better continuous drive operation

- Low vibration during low speed drive and high torque during high speed drive

- Low current operation during mid-high speed drive

- Max. holding torque with current down mode (for vertical loads)

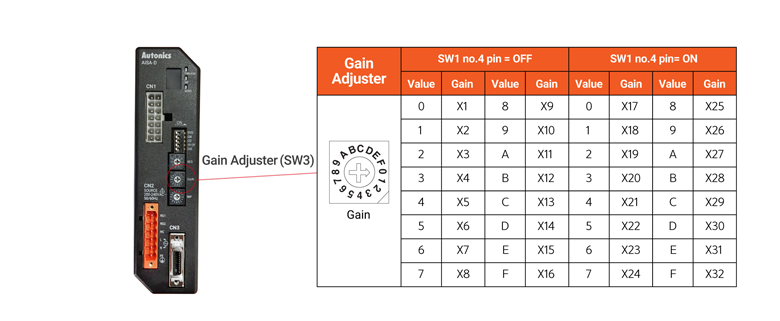

- Easy gain setting using adjuster

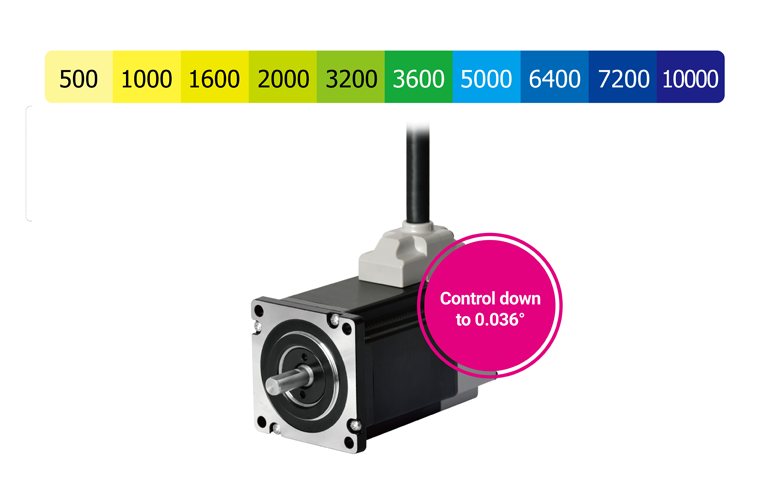

- Various encoder resolutions: 500, 1000, 1600, 2000, 3200, 3600, 5000, 6400, 7200, 10000 (10-stages)

- Various alarm outputs: overcurrent, overspeed, overheating, motor connection error, encoder connection error, etc. (12 alarms)

- Frame sizes: 60 mm, 86 mm

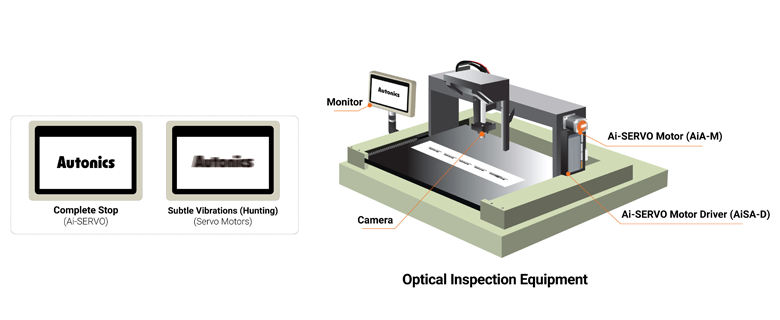

Applications: semiconductor equipment, 3D printers, optical inspection machines, SMT machines, cartesian robots, conveying equipment, alignment stages, and other precision machines.

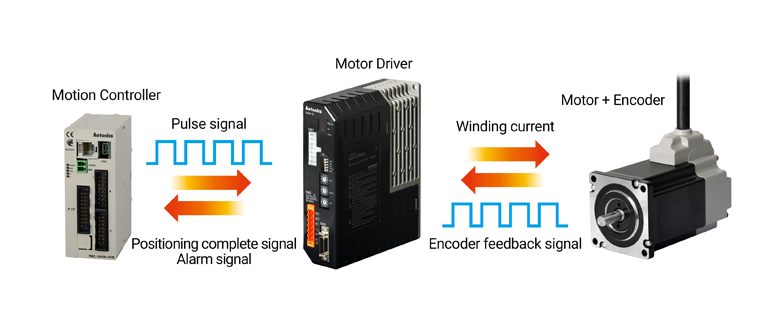

Closed Loop Stepper Motor System Set Scheme

| Power | Driver signal input | Motor frame size | Motor | Driver | SET |

|---|---|---|---|---|---|

| AC | Pulse input type | 60mm, 86mm |

AiA-M-□MA | AiSA-D-□MA | AiSA-□MA |

| AiA-M-□LA | AiSA-D-□LA | AiSA-□LA |

AC Type Closed Loop Stepper Motor System

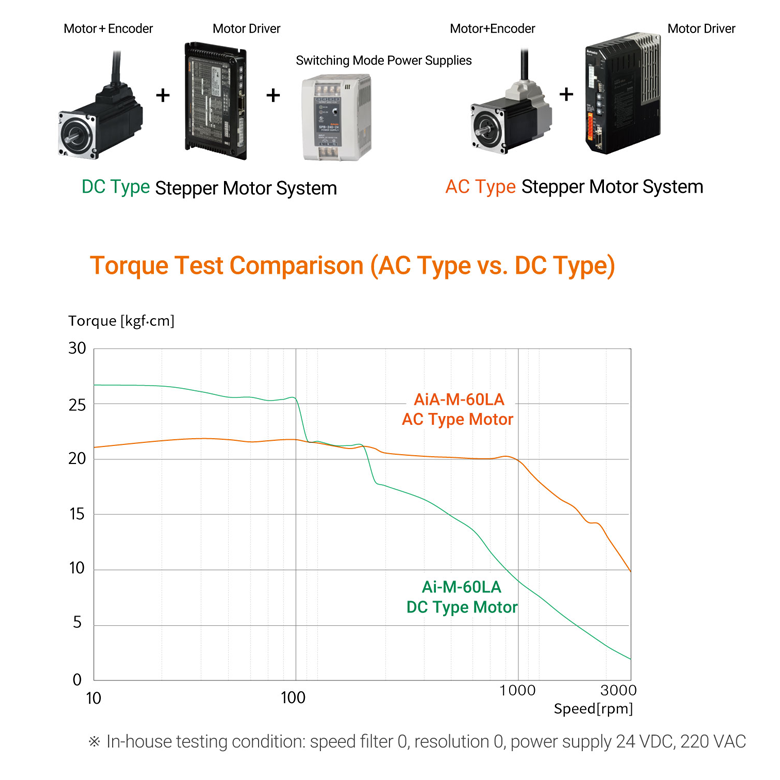

The AiSA series AC type 2-phase closed loop stepper motor system can maintain higher torque during high speed drive compared to DC type motors. The motors also do not require separate power supplies, allowing more flexible installation options.

Accurate Position Control with Quick Response Rate

The integrated encoder on the motor provides feedback of the current position in reference to the input pulse, allowing extremely accurate and precise control.

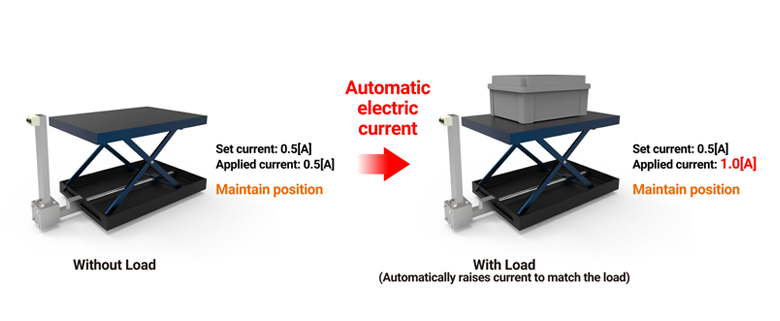

Max. Holding Torque with Current Down Mode (for Vertical Loads)

Automatic current down function reduces the electric current when the motor stops (no load) to minimize heat generation. When load is applied, the motors automatically raise the electric current to match the load up to the maximum holding torque capacity.

No Tuning Required (Easy Gain Setting Using Adjuster)

The AiSA series does not require separate tuning. Users can easily select between 32 options (0~F) using the gain adjuster.

No Hunting When Holding Position

Unlike conventional servo motors which produce subtle vibrations (hunting) when holding position, the AiSA series can hold stop position without vibration (hunting).

10-Stage Resolution for High Precision Control

The AiSA series features a 10-stage resolution setting with resolution up to 10,000 pulses per revolution, allowing precise and accurate position control down to 0.036°.

Alarm Output Function (12 Alarms) and 7-Segment Status Display

12 alarm outputs are available including overcurrent, overspeed, overheating, motor connection error, encoder connection error, and more. The status is displayed on the 7-segment alarm/operation status display on the front part the driver.