Description

- Vision sensors with integrated LED lighting

- Global shutter method for accurate image capturing with minimal motion blur

- Enhanced optical performance with light interference prevention technology

- Tight lens cover attachment allows application in environments with dust or shock

- Various inspection functions: alignment, brightness, contrast, area, edge, length, angle, diameter, object counting, color identification, color area, color object counting

- Inspection simulator function

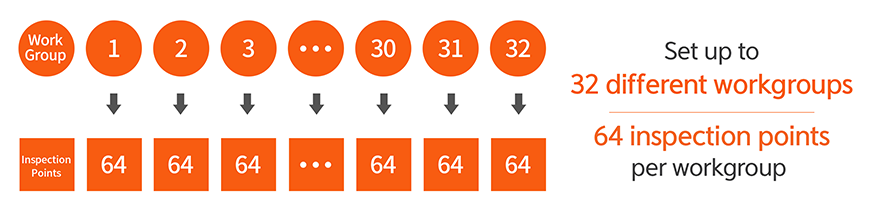

- Set up to 32 separate workgroups (64 inspection points per workgroup)

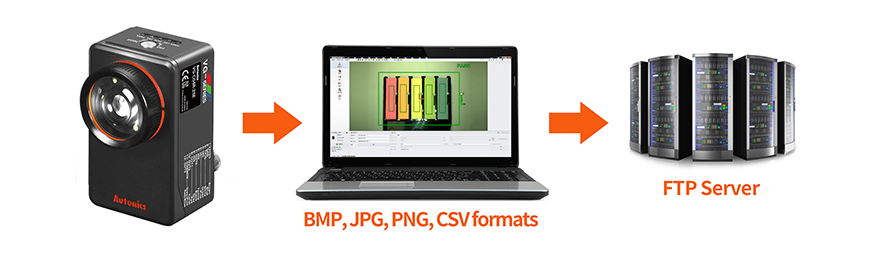

- Save data to FTP servers

- Free vision sensor software included (Vision Master) : inspection simulator function, manage parameters and workgroups, inspection results monitoring, send data to FTP, multilingual support, etc.

- IP67 protection structure (IEC standard)

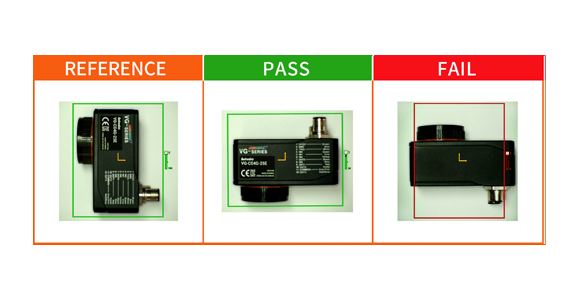

Autonics Vision Sensors with Integrated Lighting

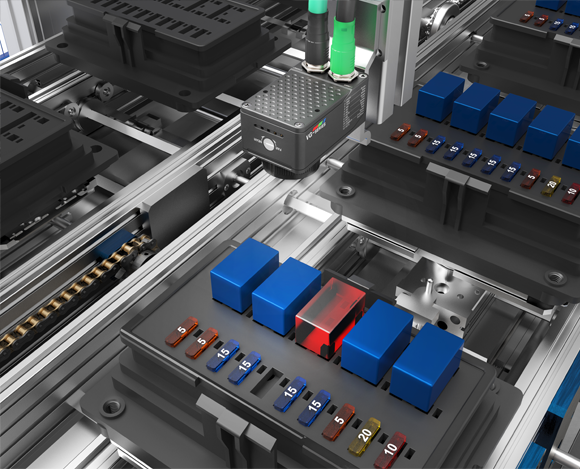

The VG series vision sensors utilize images captured by the integrated industrial camera lenses to determine the target object’s presence, color, size, shape, orientation, patterns and more. The integrated design featuring LED lighting, camera and lens allows users to set up and manage the units more easily compared to vision systems. The camera also utilizes global shutter method to capture accurate images, and the sensors feature 12 essential inspection functions for diverse applications.

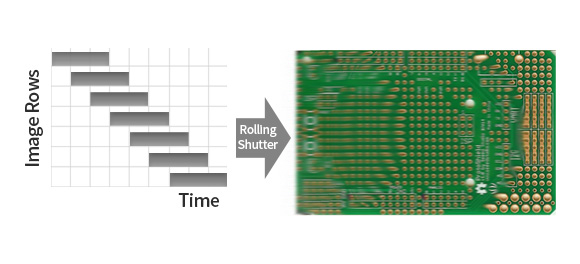

Global Shutter Method Reduces Motion Blur

The global shutter method allows the camera to capture images of fast moving targets with minimal distortion and motion blur.

Rolling Shutter

Images are captured in portions from left to right or top to bottom by rows. The time delay between each row’s exposure may cause distortion or motion blur.

Global Shutter

The global shutter method starts and ends the exposures of all rows simultaneously, removing distortions or motion blur when capturing fast moving objects.

12 Types of Inspection Functions

The sensors feature 12 different essential inspection functions including color identification, color area, color object counting, alignment, brightness, contrast, area, edge, length, angle, diameter, object counting.

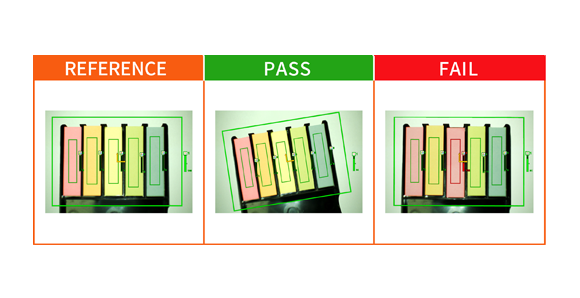

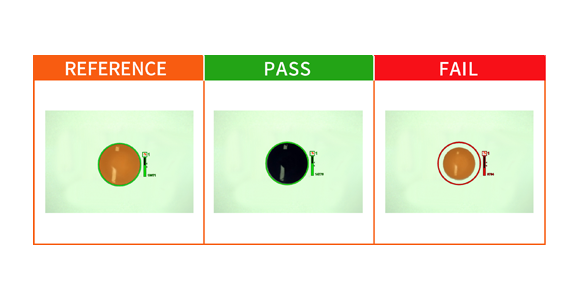

Color Identification

Inspects the color of the captured image’s ROI (region of interest) in reference to the color of the registered image’s ROI.

Color Area

Inspects the color area of the captured image’s ROI (region of interest) in reference to the color area of the registered image’s ROI.

Color Object Counting

Inspects the number of specific colored objects in the captured image’s ROI (region of interest) in reference to the registered number of colored objects in the registered image’s ROI.

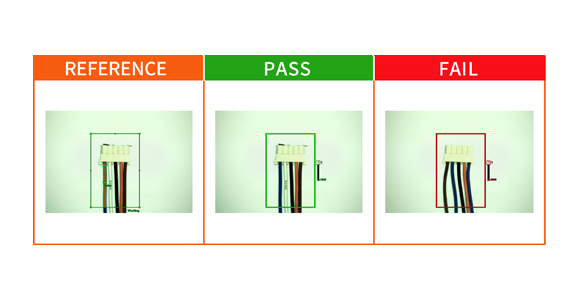

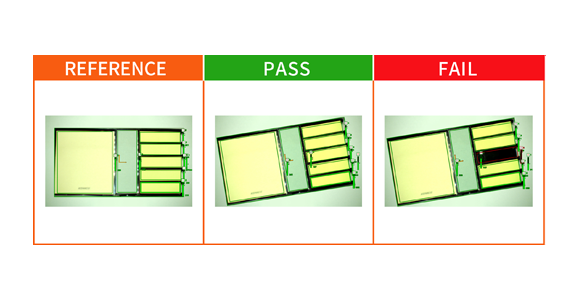

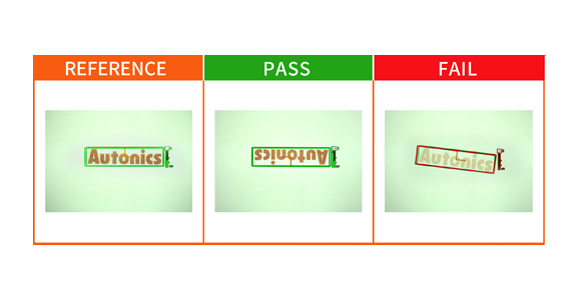

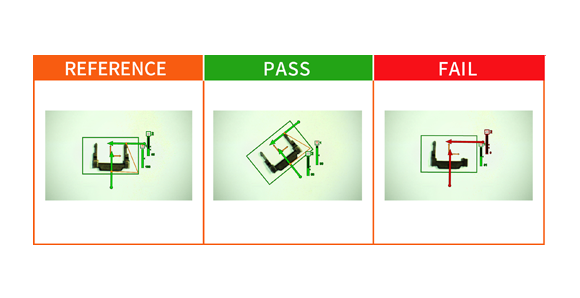

Alignment

Inspects the characteristics of the captured image in reference to the registered image, comparing the location and angle of similar patterns.

Brightness

Inspects the brightness of the captured image’s ROI (region of interest) in reference to the average brightness of the registered image’s ROI.

※ Brightness is identified after the color images are converted to monochrome images.

Contrast

Inspects the contrast of the captured image’s ROI (region of interest) in reference to the contrast of the registered image’s ROI.

※ Contrast is identified after the color images are converted to monochrome images.

Area

Inspects the area of the captured image’s ROI (region of interest) in reference to the area of the registered image’s ROI.

※ Area is identified after the color images are converted to monochrome images.

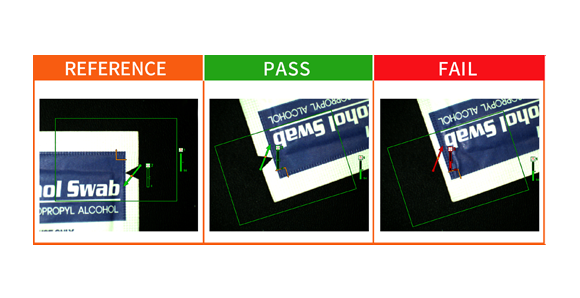

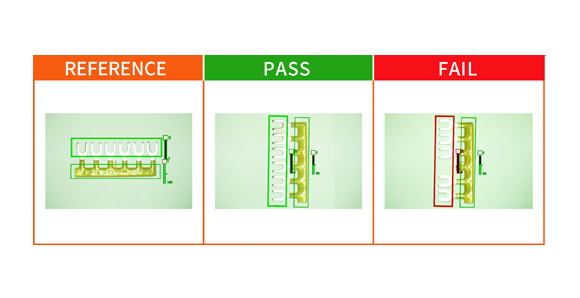

Edge

Inspects the direction of the edge of the captured image in reference to the edge location of the registered image.

Length

Inspects the captured image in reference to the length set by the user between two edges of the registered image.

Angle

Inspects the captured image in reference to the angle set by the user between two edges of the registered image.

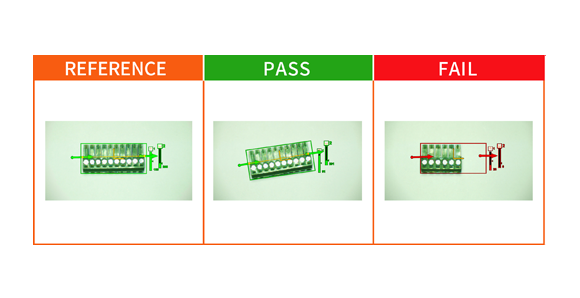

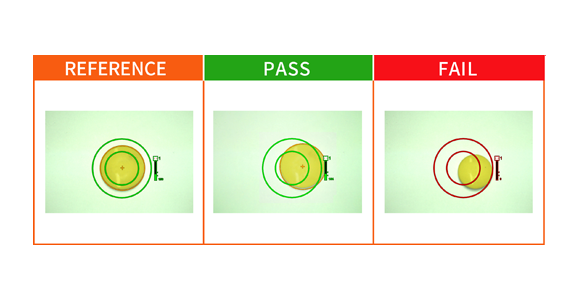

Diameter

Inspects the captured image in reference to the two diameters set by the user for the registered image.

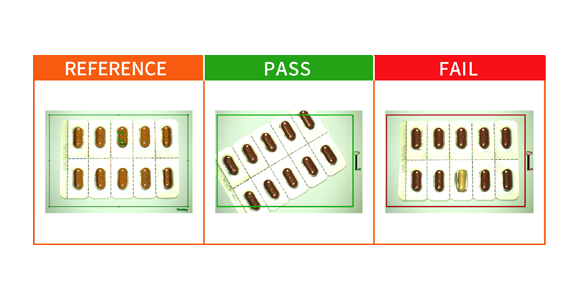

Object Counting

Inspects the number of objects in the captured image’s ROI (region of interest) in reference to the registered number of objects in the registered image’s ROI.

Set Up to 32 Workgroups

Users can set up to 32 different workgroups and up to 64 inspection points can be set up per each workgroup.’

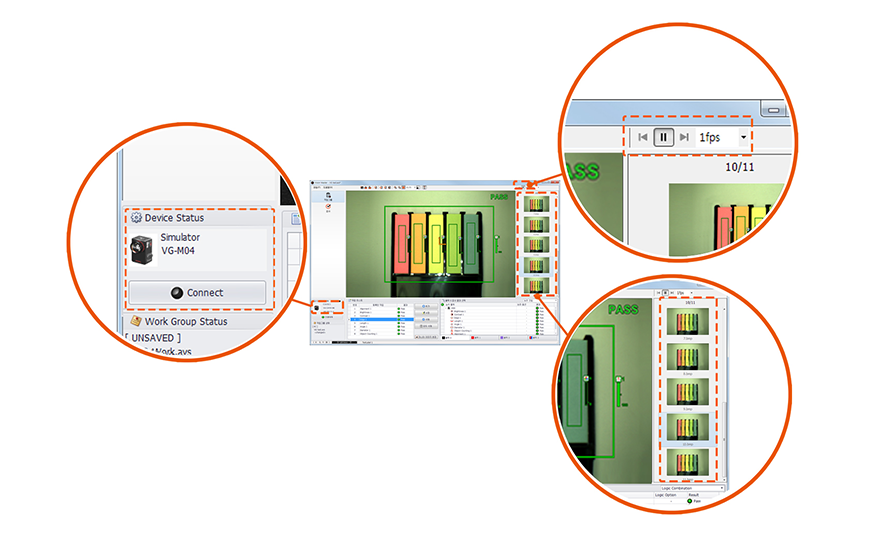

Inspection Simulator Function

With the simulator function, users can check and edit program settings or simulate inspections with saved images even when the VG series sensor is not connected.

Save Data to FTP Servers

The image data captured by the VG series can be transferred and stored to FTP servers. Depending on the configuration, users can choose to save all images, pass images only, or fail images only, making it easy to view, manage and analyze the stored data.

Various Filters Available for Accurate Inspection

With 4 different color filters and 5 different polarizing filters available, the sensors offer high performance inspection in various environments. The filters can be replaced easily and are sold separately.

Free Vision Sensor Software (Vision Master) Provided

The Vision Master software allow users to directly set parameters, monitor inspection data and more with an easy-to-use, intuitive graphic UI design.

IP67 Protection Structure (IEC Standard)

IP67 protection structure allows stable and error-free operation even in wet or dusty environments.